Panel Builder

| Description | Software | Materials |

Description

The PanelBuilder systems from Axyz Automation are world leading CNC routing solutions designed specifically for the aluminium composite (ACM) market. By combining an advanced, easy to use software solution with a custom machine design, it is now possible to process ACM materials faster, more consistently and at a lower cost than ever before.

With the Axyz PanelBuilder system you will be able to design and machine finished panels in one flawless operation without the need to move panels from one station to another leaving the panel ready to be folded.

Use the Axyz PanelBuilder system to:

- Reduce lead times

- Increase efficiency

- Reduce production costs

- Minimise waste and scrap material

- Improve quality Increase profits

The primary application of the PanelBuilder solution is the machining of aluminium sheet stock into fabricated panels. It is also suitable for other composites such as stainless steel, titanium, copper and zinc.

The conventional approach to the production of these panels has been to use panel saws, guillotines, notchers and turret punches. This is all extremely labour intensive and requires panels to be continually moved from one station to another. Consistency and reliability of output is also a major issue where multiple machines and operators are involved.

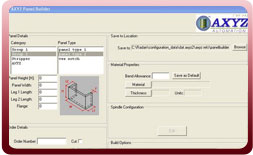

The PanelBuilder solution starts with the software which operates in 2D and 3D and allows users to quickly and easily build up a library of panels by either using the built in powerful drawing package or by importing existing drawings. The software will then automatically generate machine toolpaths for cutting all of the panels on the Axyz router.

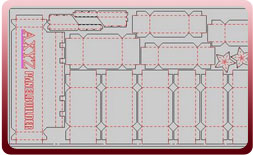

Typically, hundreds or even thousands of panels will be required in a single project. It is therefore important to maximise the material utilisation to reduce costs and keep scrap to a minimum. Panelbuilder incorporates a sophisticated nesting algorithm which can cope with both simple and complex panel geometry to reduce process time and maintain high levels of efficiency.

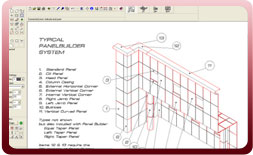

The Axyz CNC routers with their well established dual and triple head configurations are ideally suited to the processing of composite materials. Most applications require either two or three tools to process the sheets. To cope with this, other conventional CNC routing solutions have required the use of an automatic toolchange system which significantly increases the machining cycle times

|

|

|

The Axyz twin and triple spindle machines eliminate the need for a toolchanger and therefore allow much faster processing times. Typically, one spindle would have a V or ball nosed tool for cutting the fold lines, a second spindle would have a straight tool for cutting the panel out and a third spindle would be used for drill holes. Switching between tools is all handled automatically by the machine controller and results in a fast, seamless machining operation.